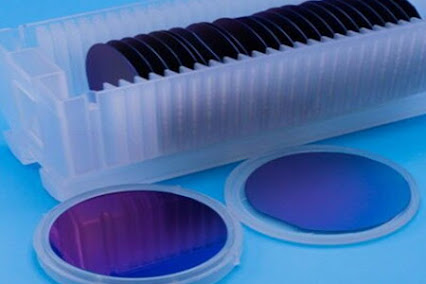

Prime-grade 4 inch Silicon Wafer are round, flat

semiconductor discs made from natural mono-crystalline silicon. The crystals

are grown at the floor of the wafer and that they outline the stages of

electrical conduction in a chip. Silicon is likewise used as a raw fabric for

microchips and transistors because it is cheaper and clean to purify. A 4-inch

Silicon Wafer is actually

one of the many extraordinary forms of wafers

utilized in a manufacturing or studies laboratory. These wafers may be

everywhere from 165 mm to 260 mm lengthy and eighty-4 mm to 120 mm huge.

Reliability

4-inch diced Silicon Wafer with a dry oxidecoating are reliable in several applications and might face up to excessive

temperatures without diminishing their sign or electricity quality. That way

you may get higher performance and utilize your Silicon Wafers for many years

with much less downtime than different devices.

Diced Silicon Wafer With A Dry Oxide Coating

|

|

Scalability

You can effortlessly cut, peel, dice, and form

Silicon Wafers into any size to suit your utility needs. If Silicon comes in

4-inch diameter sheets, you could use them as they arrive or divide them up

into smaller portions that healthy your project specifications.

Expeditious Production

The procedure of fabricating Silicon Wafers is

brief and clean for any size, form, or utility requirement. 4-inch Silicon

Wafers are easily cut, diced, and fashioned into any length required to suit

your needs.

High-speed Silicon Wafer fabrication

It is clean to fabricate 4-inch Silicon Wafers at a

totally high velocity as compared to different merchandise and production

methods. The gadgets that use those wafers require excessive speed but

additionally low fee of manufacturing because they may be used for a huge

variety of applications requiring excessive precision inclusive of

instrumentation, communications, and microelectronics.