Solidified silica quartz can also be utilized

to make troublesome shapes because of the way that the quartz material has

momentous warm deaden obstruction and are unbelievably reliable to most

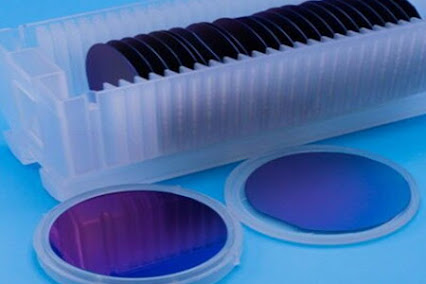

engineered fragments and mixes incorporating Diced silicon

wafer with a dry oxide coating.

Such quartz can oversee the high assembling of

acids and not be affected. The essential danger that impacts the Polystyrene

nanoparticles would be hydrofluoric ruinous. Truth be told, even in low center

this would oppositely impact the material. Stream channel cuvettes conveyed

using this material are much of the time utilized for applications, for

example, stream cytometry, molecule checking, iota surveying, and different

applications.

|

| P-type Boron-doped 200nm SiO2 thermal oxide wafer |

Joined quartz and consolidated Polystyrene

microparticles are sorts of glass that are by and large contained silica in its

non-clear design. They are conveyed a few novel strategies. The quartz

illustrated by warming the material to its molding point and quickly cooling it

(called splat-covering or dissolve extinguishing) are suggested as polished.

This term is tantamount to utilizing the word glass, for instance glass quartz.

Joined quartz or silica is passed on by consolidating

high goodness silica in an uncommon radiator. This system is done at incredibly

high temperatures, more than 1,000 degrees Fahrenheit.

Conveyed using a high centralization of

silicon-rich engineered blends, P-type Boron-doped 200nm SiO2 thermal oxide wafer, made quartz is reliably shaped utilizing a constant fire hydrolysis

measure. This strategy joins manufactured gasification of silicon, oxidation of

this gas to silicon dioxide, and warm mix of the subsequent development

(notwithstanding the path that there are elective frameworks).

The result of this procedure is an immediate

quartz glass material with preposterously high flawlessness and the best

optical transmission in the huge UV likewise called breath-taking, regardless

called the far splendid reach.

No comments:

Post a Comment