Most

of us out there have used the silicon wafer and we don’t even know about this.

Now you might be thinking that when you have used this material and how. Well,

the electronic items that we are using on a daily basis are the items for which

this material is used. To make the functions of these electronic items safe and

convenient these silicon wafers are used for them in great numbers these days. This

material is primarily used to make the semiconductors. And these are the items

that you can easily found with most of the electronic items and applications

that we use on a daily basis these days. Without these electronic items, our

daily life can really suffer. So these items are very vital for us. And the use

of the prime-grade 4 inch silicon wafer

has really managed to make the use of these electronic items safer and

convenient.

|

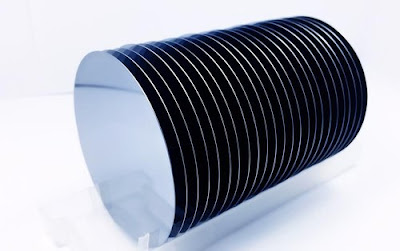

| Diced Silicon Wafer with a Dry Oxide Coating |

- Used to make semiconductors

As

far as the silicon like material is concerned, this is the next most available

material found in the universe. This material is present at almost every planet

and our earth is not excluded from this list. On the earth, silicon is present

in great amount. Diced silicon wafer with a dry oxide coating is now available online. Now you can avail this

material easily online and in affordable price.

- Comes with a mirror like finish

It’s the electronic and technology sectors where the silicon wafers are used in great numbers to make semiconductors that make the use of the electronic devices safer and easier. These silicon wafers come with a polished and mirror like finish.