Introduction:

When it comes to scientific experimentation, accuracy is not only desirable

but also necessary to provide results that can be trusted. Here are the humble

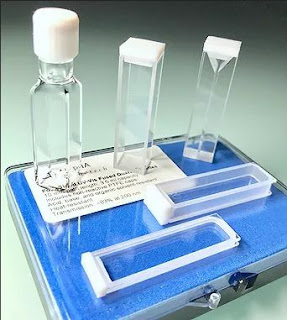

but incredibly useful quartz 10 mm cuvettes with stoppers, which are essential

for attaining accuracy in a wide range of scientific endeavors.

Starting the exploration of 10mm quartz cuvettes requires first realizing how crucial accuracy is to scientific research. These stopper-equipped cuvettes become essential instruments, guaranteeing the precision and dependability of analytical outcomes.

Navigating 10mm Quartz Cuvettes:

Understanding the features and dimensions of 10 mm quartz cuvettes with stoppers is key to appreciating their significance. The 10mm size offers

unique advantages, making these cuvettes ideal for applications where precision

is non-negotiable. The optical clarity and transparency inherent in quartz

material contribute to meticulous sample analysis, leaving no room for

ambiguity.

|

| 10mm Quartz Cuvettes with Stoppers |

The Role of Stoppers in Precision:

Stoppers, often overlooked, play a pivotal role in enhancing the precision

of cuvettes. By creating a sealed environment, stoppers contribute to the

stability of the cuvette, preventing contamination and preserving sample

integrity throughout the analytical process. Their small size belies their

significance in ensuring the accuracy of scientific results.

UV Fused Quartz Cuvettes vs. Traditional Materials:

Comparing cuvette materials brings us to the spotlight on UV Fused Quartz Cuvettes. Its advantages over traditional materials, especially in

terms of UV transparency, make it an invaluable asset in applications involving

ultraviolet light. Researchers benefit from obtaining results without

interference from the cuvette material itself, ensuring the highest level of

accuracy.

Applications and Best Practices:

10 mm quartz cuvettes with stoppers find their place in a

spectrum of scientific disciplines, from chemistry to life sciences. To

optimize their performance, adhering to best practices in handling and cleaning

is crucial. Proper care ensures the longevity of these cuvettes and maintains

consistent performance across various laboratory settings.

Real-world Examples:

The efficacy of 10mm quartz cuvettes with stoppers is best illustrated

through real-world examples. Case studies highlight instances where precision

played a pivotal role in achieving ground breaking results. Whether in spectroscopy

or chemical analysis, these cuvettes showcase their adaptability in diverse

research areas.

Conclusion:

In conclusion, for those seeking precision in analytical processes, 10mm quartz cuvettes with stoppers emerge as reliable allies. Their

optimal size, combined with the transparency of UV Fused Quartz Cuvettes, makes them indispensable tools for

researchers demanding the utmost accuracy in their work. As we navigate the

intricacies of scientific exploration, these cuvettes provide a clear path

forward, ensuring that every experiment is conducted with the highest level of

precision.