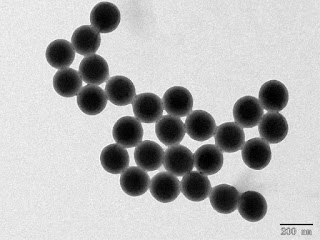

As silica nanoparticles are more

frequently studied for usage in drug delivery systems, their properties must be

sequentially optimized to reduce or remove any hazardous qualities that have

been observed. The cytotoxicity of silica nanoparticles has been discovered to

be directly correlated with their size, dose, cell type,

duration of treatment, surface area, and structural discrimination. The great

chemical stability, biocompatibility, and targeted and controlled release of

silica nanoparticles are distinctive characteristics. The increased stability

is a result of the silica's single bond O bond. They have demonstrated its use

in tumor-specific medication targeting, cell tracing and biosensing, and

diagnostic tools.

|

| Polystyrene Nanoparticles |

Due to their biocompatibility and

simplicity in manufacturing, silica nanoparticles are the most crucial kind for

drug administration since they allow for surface customization. Silica

nanoparticles are suitable candidates for drug carriers because of their tiny

size and adaptable surface modification. Because mesoporous silica has a large

number of empty pores, a significant amount of active moiety can be contained

within it. For the regulated release of medicinal drugs, silica nanoparticles

make an excellent candidate because of their enormous surface area, pore

volume, and great stability. Solid, nonporous, and mesoporous silica

nanoparticles are the three basic varieties. Silica nanoparticles have

developed into a crucial system for biological imaging and the administration

of medications and genetic material because of their chemical and physical

stability, well-defined hydrophilic surface, and capacity to protect drugs from

an aggressive immune response. Go ahead! And claim the top benefits and

advantages of world-class silica

nanoparticles and polystyrenenanoparticles.

%20Microspheres.jpg)