For

a wide range of applications and tests, we need the nano particles these days.

These are also called as the microspheres and they are used in great numbers

and different forms these days to conduct a wide range of tests and

experiments. When you are doing these tests, you are also expecting to receive

accurate outcome. Before this used to be very tough and after doing several

tests, scientists and lab technicians used to receive right result. But the use

of the nano particles has really changed the whole scene.

|

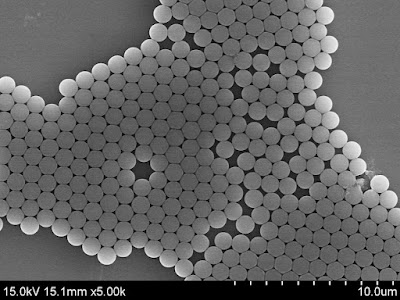

| PMMA Nanoparticles |

- Use the right nanoparticles

Now

when you have the right nano particles to do the tests with different

applications, you can also expect to receive accurate readings and results at

the first instance. It’s the poly

(methyl methacrylate) microspheres which are used in the medical technology

life field in great numbers. These are also used for the implants. In order to

make the intraocular lenses that are rigid enough these nano particles are also

used. In order to fabricate the orthodontic appliances, artificial teeth and

dental prosthetics, these nanoparticles are also used.

- Strong resistance against scratches

When it comes to the PMMA nanoparticles, these are now taken as the best substitute for the plastic and glass when it comes to the making of aircraft canopies, illuminated signs, and skylights and shatter proof windows. These nano particles are very stable against the UV light. Due to this reason, they are also used for the outdoor applications. When used for these applications, the nano particles also help to maintain the finish and color for a long time. PMMA like material used to have a very strong resistance against scratches.