When it comes to the manufacturing of electronic devices,

the use of the semiconductors means a lot. In order to get the right kind of

semiconductors or to make them, the material like silicon is considered on a

high node. This might be a reason why the use of the silicon wafer has managed to draw most attention these days when it

comes to the making of the electronic devices. The use of such a wafer as the

semiconductor keeps the whole system and further operation of the electronic

device safe enough. There are certain complex things associated with electronic

devices. However, the use of silicon for these devices is always taken as a

simple by the very vital thing. These days, you can find that these wafers are

used from making the supercomputers to the android devices and even the

microwave ovens. So, this leads us to question why silicon is used and not any

other material.

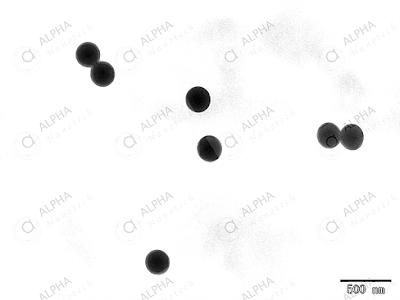

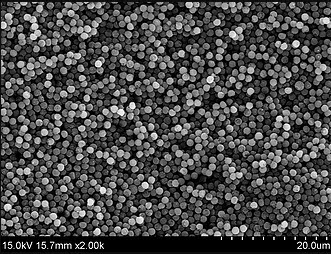

| Silicon wafer |

- Use the prime grade one

Silicon carries some special properties. This element comes

with the vital properties which are also important to note when it comes to the

making of the electronic devices. There are also different grades of silicon

wafers. And the prime-grade silicon substrate

has really managed to draw the most attention in this segment. There are also

test grade and mechanical grade silicon wafers that you can avail now.

- Silicon carries vital properties

Well, the prime grade one can be used for a wide range of

applications and this also includes the production. The integrated circuits

that you see in the computers are made from this grade of the silicon wafer.