Tiny particles, vast potential: Poly(methyl methacrylate) (PMMA)

microspheres are microscopic plastic spheres with a surprisingly broad range of

applications. This article delves into Alpha Nanotech, a leading manufacturer

of these versatile materials, exploring their product offerings and the science

behind their precise sizing.

A Spectrum of PMMA Nanoparticles:

Alpha Nanotech boasts a diverse portfolio of PMMA microspheres, catering to

various needs through:

Tailored Sizes: Their products range from 300

nanometers to 50 microns, ensuring a perfect fit for diverse applications.

Consistent Quality: With a coefficient of variation (CV)

below 5% for most sizes, their microspheres offer exceptional uniformity.

Unmatched Roundness: Roundness exceeding 0.98 ensures

consistent behavior and predictable performance in various applications.

Beyond the Product: Unveiling the Science of Sizing

Alpha

Nanotech prioritizes accurate sizing, employing advanced techniques like:

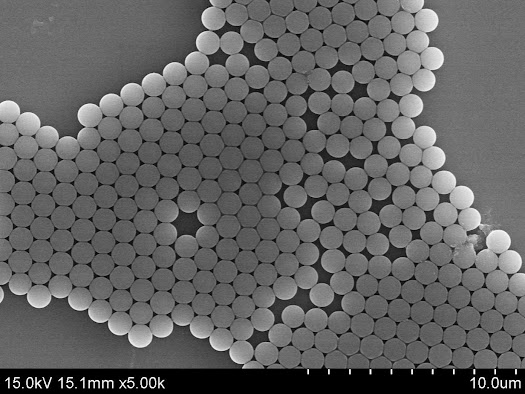

Scanning Electron Microscopy (SEM): Offers high-resolution imaging for

precise size determination.

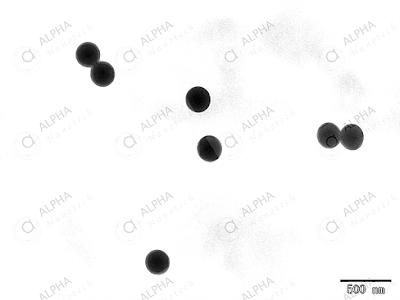

Transmission Electron Microscopy (TEM): Provides detailed internal structure

visualization, complementing size measurements.

While

Dynamic Light Scattering (DLS) is a common technique, Alpha Nanotech

discourages its sole reliance for PMMA nanoparticles due to potential

inaccuracies.

%20Microspheres.jpg) |

| Poly (Methyl Methacrylate) Microspheres |

Why Choose Alpha Nanotech?

Extensive Selection: Their diverse product range caters to

various applications in drug delivery, cosmetics, paints, electronics, and

beyond.

Unwavering Quality: Their commitment to state-of-the-art

manufacturing ensures consistent quality and reliable performance.

Customization Options: They offer custom manufacturing

services to meet your specific requirements.

Knowledge Hub: Their website provides comprehensive

resources, including technical data sheets, application notes, and safety

information.

Expert Support: Their experienced customer service

team is readily available to answer your questions and guide you towards the

ideal PMMA microspheres for your needs.

In

Conclusion:

Alpha Nanotech stands out as a leading provider of high-quality Poly (Methyl Methacrylate) Microspheres. Their commitment to diverse offerings, meticulous sizing techniques, and exceptional customer support make them a trusted partner for various industries seeking the potential of these versatile materials.