Introduction to Nanomaterials:

When we explore the nanoworld, we find a broad array of minuscule yet powerful materials that have the potential to transform a number of different industries. Among these, non-functionalized silica nanoparticles and iron oxide beads covered with silica stand out for their special qualities and uses. Knowing the differences between these two can help determine which is more suited for what.

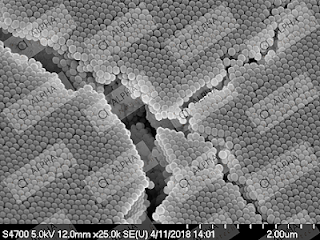

Iron Oxide Beads Coated with Silica:

- Overview: These are tiny

particles with a core of iron oxide that is encased in a layer of silica.

This combination harnesses the magnetic properties of iron oxide and the

chemical stability of silica, making them a versatile choice for several

applications.

- Advantages: The core-shell

structure of iron oxide beads coated with silica brings forth a

blend of magnetic functionality and surface modifiability. This makes them

ideal for tasks like magnetic separation in biotechnology, targeted drug

delivery, and contrast agents in magnetic resonance imaging (MRI).

- Considerations: Their utility is

particularly pronounced in applications that benefit from magnetic

properties, combined with the need for a stable, modifiable surface.

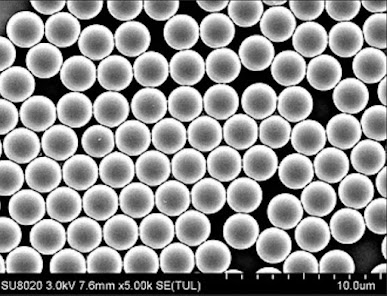

Non-functionalized Silica Nanoparticles:

- Overview: In contrast, Non-functionalized

silica nanoparticles 1�m are

simple, pure silica particles without any surface modifications or

coatings. Their simplicity is their strength, offering a broad canvas for

chemical modifications.

- Advantages: The purity and

versatility of non-functionalized

silica nanoparticles make them suitable for a wide range of

applications, including as carriers in drug delivery systems, in

cosmetics, and various industrial applications requiring a silica base.

- Considerations: Opting for these

nanoparticles is advantageous when the application requires a

straightforward silica material that can be customized through further

chemical modifications.

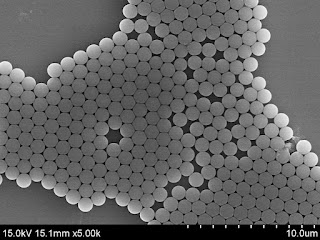

Iron Oxide Beads Coated With Silica

Comparing and Choosing:

- Application-Based Decision Making:

The choice between iron oxide

beads coated with silica and Non-functionalized silica nanoparticles 1�m should be guided by the

specific requirements of the project. Whether the need is for magnetic

properties and surface modifiability or for a simple, versatile silica

base will determine the most suitable option.

- Aligning Material Properties with Goals:

Matching the unique characteristics of each nanoparticle type to the

desired outcomes of your project is crucial for maximizing their potential

benefits.

Conclusion:

The decision to use iron oxide beads coated with silica versus Non-functionalized silica nanoparticles 1�m involves strategic consideration of each

material's properties and how they align with the project's goals. By

understanding the distinct advantages of each, researchers and developers can

make informed choices, leveraging the right nanomaterials to push the

boundaries of innovation and application in their respective fields.