Introduction:

In the realm of semiconductor

technology, silicon wafers are the building blocks that enable the production

of integrated circuits and electronic devices. These wafers undergo various

processes and enhancements to meet the stringent requirements of the industry.

In this blog post, we will explore the fascinating world of diced silicon

wafers with a dry oxide coating, focusing on the prime-grade 4-inch silicon

wafers and their significance in semiconductor manufacturing.

Understanding

Diced Silicon Wafers with Dry Oxide Coating:

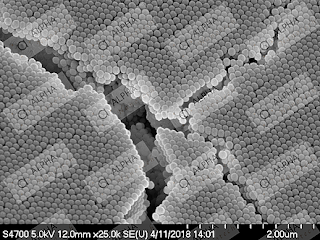

Diced silicon

wafer with a dry oxide coating refer to the process of cutting a

single large silicon wafer into smaller individual pieces or dies. Each diced

wafer serves as a substrate for the fabrication of individual electronic

components. To enhance the performance and reliability of these diced wafers, a

dry oxide coating is often applied.

Dry oxide coating is a thin layer of

silicon dioxide (SiO2) that is thermally grown on the surface of the diced

silicon wafers. This oxide layer provides a protective barrier, preventing

contamination, reducing surface defects, and improving the electrical

insulation properties of the wafer.

Prime-Grade

4-Inch Silicon Wafers:

Prime-grade4-inch silicon wafers

are considered high-quality substrates widely used in semiconductor

manufacturing. The term "prime-grade" signifies the highest level of

purity and quality among silicon wafers. These wafers undergo a stringent

selection process to ensure minimal defects, uniform thickness, and superior

crystal structure.

| Prime-grade 4 Inch Silicon Wafer |

Applications and

Benefits of Diced Silicon Wafers with Dry Oxide Coating:

Integrated

Circuit Fabrication: Diced

silicon wafers with a dry oxide coating are fundamental in the production of

integrated circuits. The diced wafers serve as the foundation for the

deposition of various layers, including semiconductors, metals, and

dielectrics, enabling the creation of intricate circuitry. The dry oxide

coating acts as an insulating layer, preventing leakage currents and improving

the reliability of the fabricated circuits.

MEMS

(Micro-Electro-Mechanical Systems): Micro-electro-mechanical systems,

commonly known as MEMS, are miniature devices that combine mechanical and

electrical components on a single chip. Diced silicon wafers with a dry oxide

coating are essential in the fabrication of MEMS devices, as they provide a

stable and reliable substrate for the deposition and integration of mechanical

and electrical elements.