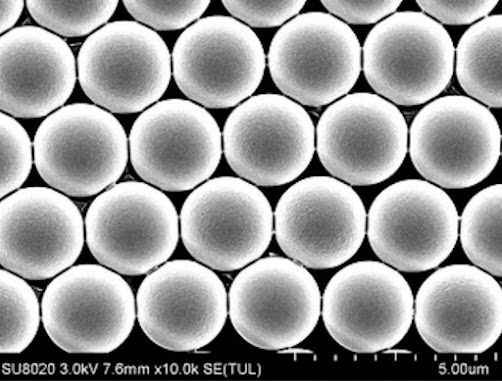

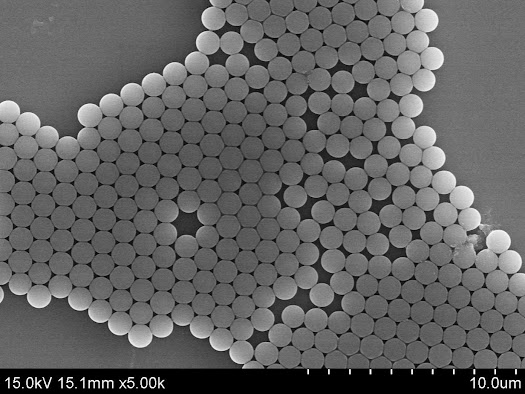

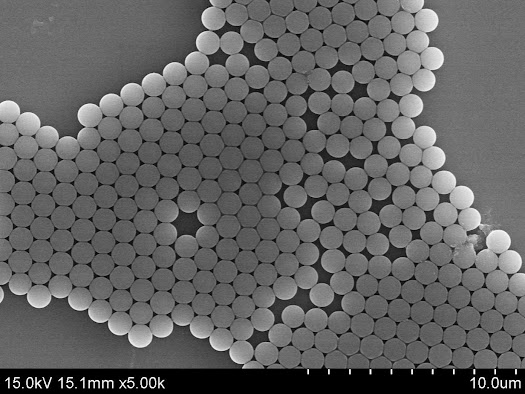

Poly(Methyl Methacrylate)

Microspheres (PMMA) is a

lightweight, manufactured polymer that is a prudent option to polycarbonate

when very high strength isn't required. A benefit is that PMMA doesn't contain

potential hurtful subunits like bisphenol-A found in polycarbonate. Also, the

manufactured polymer is simpler to deal with, measure, and more affordable than

polycarbonate.

PMMA nanoparticles have extraordinary

mechanical properties and low harmfulness. While being well known for hip-joint

transplantations in light of its latent properties, PMMA shows moderate

corruption. In this way, making a polymer mix of polycaprolactone with PMMA

produces a polymer material that is more qualified for biomaterial

applications.

|

| PMMA nanoparticles |

The examination

tracked down the mixed polymer material appropriate for osteoblast cell

expansion. Additional proof of confocal pictures and articulation of expansion

cell atomic antigen affirmed multiplication and articulation of cells in the

7:3 PCL: PMMA mixed polymer climate. PMMA is a non-biodegradable polymer used in

applications that require perpetual, precisely stable constructions, for

example, bone tissue recovery.

Polymethylmethacrylate

was first evolved by German scientific expert Otto Rohm in 1901 (Rohm, 1901).

In 1943 it was additionally refined into a batter-like-functional structure by

Kulzer and Degussa organizations (Kuehn et al., 2005). Their advancements

ultimately prompted the arrangement of cold-restored PMMA, which solidifies at

room temperature (Kuehn et al., 2005). In its most punctual wellbeing applications, PMMA was principally utilized in the field of dentistry.

The various

benefits of Poly Methyl Methacrylate (PMMA) make it the most prevailing polymer

utilized as dental replacement base material. The simplicity of preparing,

minimal expense, lightweight, security in the oral pit, and tasteful

properties are of these benefits. PMMA tar dental replacement base material has

helpless surface properties and frail mechanical properties including sway and

flexural qualities. In this way, saps ought to be supported utilizing various

materials to improve their properties. As of late, nanotechnology attacked the

dental field and started insightful examination ventures to investigate the

potential applications and anticipated advantages inside dentistry.