It's difficult to list the various uses or assortments of quartz precious stones even in a book. Since the old occasions, quartz has been utilized in practically all circles of life like mending, assurance, gems and numerous different purposes.

Quartz is found in various shapes and sizes on the earth. Purple quartz is known as amethyst while pink quartz is known as rose quartz. At the point when quartz gains a yellow shading, it known as citrine while drab quartz is known as shake quartz. There is a great deal of intriguing random data about quartz gem since the very beginning. Individuals of the famous island Atlantis used to bridle the vitality of the sun with precious stones like borosilicate glass beads. In the Orient, these gems were cut and utilized for remedying a wide range of vision issues.

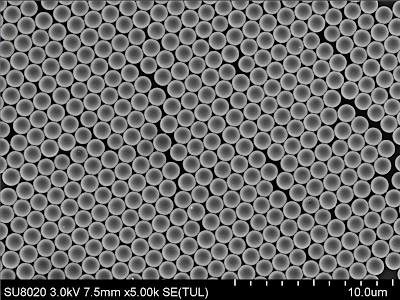

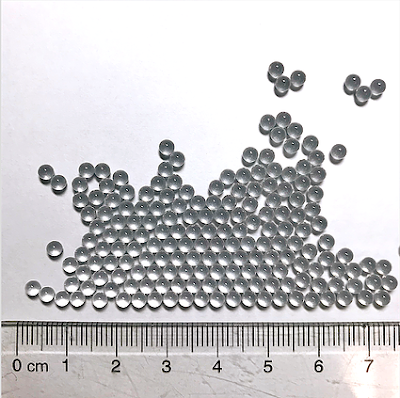

|

| Borosilicate glass beads |

Uncommon quartz arrow points were utilized by individuals close to the Arkansas River in 8000 B.C. Formal weapons made out of clear quartz like blades, scrubbers and shot focuses were made as old as 700 to 1000 A.D.

Quartz additionally has piezoelectric property which is to state that on the use of a little electric charge, the precious stone vibrates like the stainless steel disruption beads. This is the motivation behind why it is utilized watches. It additionally has a property known as triboluminescence which implies that a sparkle is delivered when two quartz pieces are scoured together.

Quartz has been around since the get-go. In spite of the fact that we have found its uses in science, there is a ton of work to be done as far its mystical properties and their pragmatic ramifications are concerned.