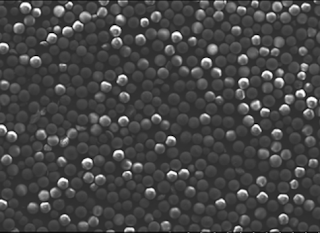

Silica

nanoparticles have a variety of interesting properties and therefore a wide

range of applications. They are strong, abrasive materials that can be used to

polish silicon wafers. They effectively reduce friction and are therefore used

to coat waxed floors and even railway tracks. Because of their absorbent

properties, they are useful as a drainage aid in papermaking. They can serve as

binding agents in the production of rubber, plastics and concrete. In

particular, they are stable and non-toxic materials with countless applications

in biomedicine.

The

power of premium silicon wafers:

Silica nanoparticles are

known for their exceptional quality and purity. These wafers are carefully manufactured

to meet the industry's most stringent standards, ensuring minimal defects and

excellent electrical properties. The 4-inch size is a popular choice for a

variety of applications due to its versatility and cost-effectiveness.

|

| Silica Nanoparticles |

Cubed Silicon Wafers:

One

of the advantages of using Diced silicon wafer with a dry oxide coating is the ability to customize the size and shape of the wafer to

specific requirements. This process involves precise cutting, creating

individual chips or substrates that are ideal for various applications such as

microelectronics, photovoltaics and MEMS (microelectromechanical systems).

Electrical

Isolation: The oxide layer acts as an insulator and prevents electrical

current from flowing between the various components of the wafer. This is

crucial for isolating transistors and other electronic elements in integrated

circuits.

Surface

passivation: Dry oxide coatings passivate the silicon surface, reducing

defects and improving the overall electrical properties of the wafer.

Passivation also improves the resistance of wafers to external factors such as

moisture and contamination.

High-quality

4-inch dry oxide coated silicon wafers have applications in a variety of

industries, including:

Microelectronics: These wafers are critical to the

fabrication of integrated circuits and microchips, supporting the development

of smartphones, computers and other electronic products. Devices.

Photovoltaics: Diced silicon wafer with a dry oxide coating with a dry oxide layer are the basis of solar cells. The dry oxide coating improves the efficiency and durability of these cells, contributing to the growth of renewable.

No comments:

Post a Comment