It’s the Stobber process that is often

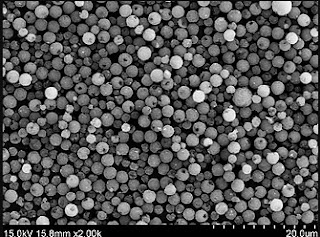

used to coat the iron oxide beads with silica. And the nano particles that are

made as a result of this process carry the silica as a coating on the iron

oxide beads. These nano particles are in great demand these days. There is a

wide range of applications for which these nano particles are used in great

numbers. And every time these microspheres have managed to deliver accurate and

fast outcome.

·

Stobber

process is followed

In order to perform this process,

reaction mixture needs to be seeded and that comprises of particles of iron

oxide which are the catalyst, ethanol, water and most importantly the silica precursor.

When the precursors are hydrolyzed and condensed, a layer of silica coating

starts to appear on the iron oxide beads. To quicken the aggregation of the

iron oxide, the iconic strength of this process is increased. Iron oxide beads coated with silica are

now available in cheap. You can get these nano particles online as well and can

get the best deal on them.

|

| Amine-terminated magnetic silica beads |

· Helps to improve the condition of infections

As per the vivo and vitro studies, there is a great importance given to the silica beads that carry the magnetic property. Amine-terminated magnetic silica beads are very useful and they are used for a wide range of applications these days. During the orthopedic surgeries, implants can be there after that invasive process. The infections associated with these implants have always remained as a matter of concern, to improve the conditions of these infections; these magnetic silica beads are also sued. These magnetic nano particles work as the drug carrier and help to improve the condition of the infections.

No comments:

Post a Comment