Nowadays,

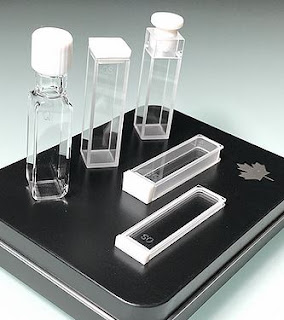

there are different types of cuvettes used for different tests and experiments

in laboratories. The cuvettes can be made of different materials such as

plastic, glass and quartz. However, quartz cuvettes have always been the first

choice when working in the UV range. UV light can be easily absorbed by plastic

and glass. For this reason, testing in the UV range with glass and plastic

cuvettes will not give you an accurate result.

There is never any interference.

Because these materials easily absorb UV

light, they can produce interference. Therefore, cuvettes made from it are not

the best option for photometric testing. In the visible light range, the

wavelength can remain very long. For this reason, quartz cuvettes are mainly

used so that accurate results can be achieved and there are no interferences.

If you are looking for UV quartz cuvettes with screw caps and PTFE septa, you

have come to the right place.

Follow standard cleaning procedures to clean

these buckets.

For photometric measurements it is always

necessary to use clean cuvettes. Ultraviolet quartz cells with PTFE screw caps and septa, can be cleaned and reused. And that undoubtedly makes them

more versatile bucket types. UV quartz cuvettes typically have four different

windows that are polished and clean. For this reason, they can help you get

accurate photometric measurements. These buckets can be cleaned using the

standard cleaning procedure.

|

| Ultraviolet Quartz Cells With PTFE Screw Caps And Septa |

A perfect laboratory vessel

A wide range of chemicals and test materials

are used in laboratories. Therefore, it is necessary to store and experience

them properly. Here the use of UV quartz cells with screw caps and PTFE septa

can make a big difference in the expected result. These are laboratory-quality

containers. While using them, you can perform your tests safely and accurately.

These items come with caps and septa. For this reason, you can store the

liquids you need for testing safely and properly.

Get

accurate measurements in the UV range

If you want to get accurate measurements when

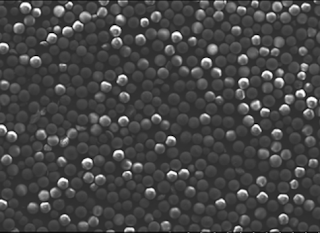

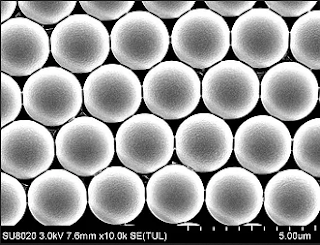

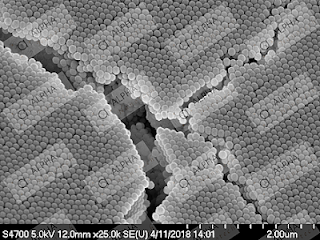

testing in the UV range, you can achieve amazing results by using P-type Boron-doped 200nm SiO2 thermal oxide wafer. It does not absorb ultraviolet

light like plastic and glass. Because of this, interference never occurs, which

ultimately helps you get accurate measurements.

%20Microspheres1.jpg)