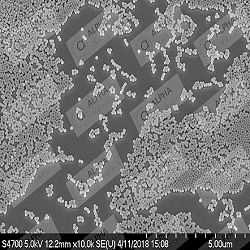

Particles of iron oxide with diameters ranging from 1 to 100 nanometers are known as iron oxide nanoparticles. Magnetite (Fe3O4) and its oxidized form, maghemite (-Fe2O3), are their two primary forms. Cancer magnetic nanotherapy can utilize iron oxide nanoparticles. They are based on semiconductor materials' ability to produce oxygen free radicals and the magnetic spin effect in free radical reactions. Under non-uniform electromagnetic radiation, they can also control oxidative stress in biological media.

What function do iron oxide

nanoparticles serve?

Nanoparticles are leading the rapid advancement of nanotechnology. These iron oxide beads coated with silica materials are essential and superior in many human activities due to their unique size-dependent properties. Due to their non-toxic function in biological systems, iron oxide nanoparticles have demonstrated significant biomedical application potential in recent years.

Additionally, iron oxide nanoparticles' magnetic and semiconductor properties may enable multifunctional medical applications. Anticancer, antifungal, and antibacterial properties have been developed for these nanoparticles. Iron oxide nanoparticles have been drug-functionalized for cancer treatment and diagnosis. There re many uses for Amine-terminatedmagnetic silica beads.

|

Amine-terminated Magnetic Silica Beads |

How are nanoparticles made of

iron oxide made?

Iron oxide nanoparticles were blended by precipitation in isobutanol with sodium hydroxide and ammonium hydroxide. In the synthesis, the isobutanol was a surfactant. The nanoparticles were calcined at temperatures ranging from 300 to 600 °C for 100 minutes to 5 hours.

What are nanoparticles of

superparamagnetic iron oxide?

The class of MRI-based contrast agents known as superparamagnetic iron oxide NPs (SPIONs) have multiple applications. In addition to their capacity for drug magnetic targeting, these iron oxide nanoparticles have clinical applications such as the detection of hepatocellular carcinomas and the treatment of cancer with magnetic fluid hyperthermia.