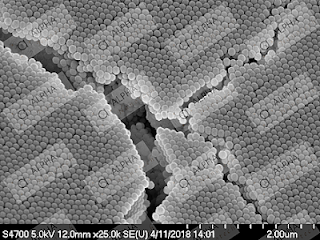

So, picture this, tiny, itty-bitty microparticles that are like the

superheroes of the nanoworld! These microparticles, whether they are

non-functionalized or rocking some carboxyl groups, are like the cool kids at

the nanoscale party.

You see, Non-functionalized or carboxyl polystyrene

microparticles are like blank canvases just waiting for an artist's touch.

They are versatile and ready to mingle with all sorts of molecules and

materials, making them the life of the nanoparticle bash!

But hey, do not overlook

their carboxyl-functionalized pals! These microparticles are like the VIPs of

the nanoparticle scene. With those carboxyl groups, they are like magnets for

other molecules, attracting them with their irresistible charm.

|

| Non-functionalized Or Carboxyl Polystyrene Microparticles |

Carboxyl-Functionalized

Magnetic Silica Nanoparticles

Now, let us talk magnetic

nanoparticles, the rockstars of the nanoworld! Imagine tiny specks of silica

infused with magnetic magic, ready to shake things up wherever they go.

But here is the kicker, when

you add carboxyl functionality to these magnetic silica nanoparticles, you are

taking them to a whole new level of awesomeness! It's like giving them

superpowers, making them even more attractive to other molecules and materials.

With these Carboxyl-functionalized magnetic silica nanoparticles, you have got a dynamic duo that is ready to tackle

challenges head-on. Whether it's biomedical applications, environmental

clean-up, or cutting-edge research, they're the dream team you want on your

side.

Mixing it up for maximum

impact

Now, here's where things get

exciting, when you bring together non-functionalized or carboxyl polystyrene

microparticles with Carboxyl-functionalized

magnetic silica nanoparticles, it is like fireworks on the nanoscale!

Think about it, you have got

the versatility and charm of the polystyrene microparticles, combined with the

magnetic magic and molecular magnetism of the silica nanoparticles. It is a

match made in nanoparticle heaven!

Together, these dynamic duos

can do it all, from targeted drug delivery to advanced imaging techniques, and

everything in between. They are breaking boundaries, pushing limits, and making

waves in the world of nanotechnology.

%20Microspheres1.jpg)