In the realm of scientific research and laboratory experiments, precision and versatility are key factors that drive innovation. One essential tool that plays a crucial role in various analytical processes is the quartz cuvette. However, the full potential of these cuvettes can only be realized when combined with high-quality sealing caps, such as those made from polytetrafluoroethylene (PTFE).

In our latest blog post, "Unlocking

Precision and Versatility: Exploring Quartz Cuvettes with PTFE Caps," we

delve into the fascinating world of quartz cuvettes and their incredible

applications. We explore how the integration of PTFE caps enhances the

functionality and reliability of these cuvettes, enabling scientists and

researchers to achieve unparalleled accuracy and flexibility in their

experiments.

|

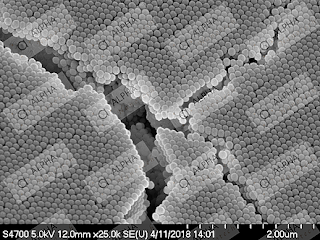

| Quartz cuvettes with PTFE caps |

Join us as we uncover the unique properties of quartz cuvettes that make them indispensable tool in a wide range of scientific disciplines, including chemistry, biochemistry, spectroscopy, and molecular biology. We'll discuss the exceptional optical clarity of quartz, its resistance to harsh chemicals and extreme temperatures, and its ability to provide accurate measurements across a broad spectrum of wavelengths.

Moreover, we delve into the importance of

PTFE caps in maximizing the performance of quartz cuvettes. PTFE is known for

its excellent chemical resistance, non-reactivity, and low friction properties,

making it an ideal material for sealing cuvettes in demanding experimental

conditions. We explore how PTFE caps effectively prevent sample evaporation,

minimize contamination, and ensure a secure and leak-free environment for

sensitive samples.

Throughout the article, we showcase

real-life examples and success stories from researchers who have harnessed the

precision and versatility of quartz cuvettes with PTFE caps to advance their

scientific endeavors. From precise spectroscopic measurements to accurate

concentration determinations, the possibilities are endless with these powerful

combinations.

Whether you are a seasoned scientist or a

curious enthusiast, "Unlocking Precision and Versatility: Exploring Quartz

Cuvettes with PTFE Caps" offers valuable insights into the world of

cutting-edge laboratory techniques. Gain a deeper understanding of how the

integration of PTFE caps elevates the capabilities of quartz cuvettes,

revolutionizing scientific research and propelling innovation to new heights.

Join us on this captivating journey as we

unravel the secrets behind unlocking precision and versatility through the

exploration of quartz cuvettes with PTFE caps. Stay tuned for our upcoming blog

post and embark on a quest to transform your laboratory experiments with the

power of advanced sealing technology.