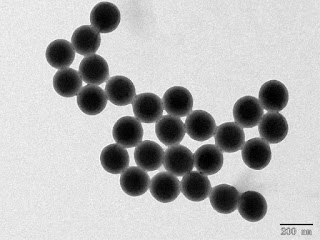

We use different nano particles these

days to ensure that our applications and processes run smoothly, deliver

accurate result and we can conduct these processes safely. When we are talking

about these nano particles, polystyrene microspheres are the ones that might

draw your attention instantly. These nano particles are something that we use

on a daily basis in our day to day life but we hardly know this. The cup

covers, CDs and toys that we use these days are made while using these nano

particles. In order to produce Styrofoam, these nano particles are also used in

great numbers.

- Used to make a wide range of products

There is a wide range of products that

we use on a day to day basis are made while using these polystyrene nanoparticles. As per the vitro and vivo studies, it

was found that these nano particles can even penetrate through the organisms

while using different routes such as digestive tracts and respiratory system.

For a wide range of applications these nano particles are used. And some of

them are very common to us such as drug delivery system, immunoassays, markers

and bioimaging.

|

| Magnetic Silica Nanoparticles |

- No cross contamination will occur

%20Microspheres.jpg)